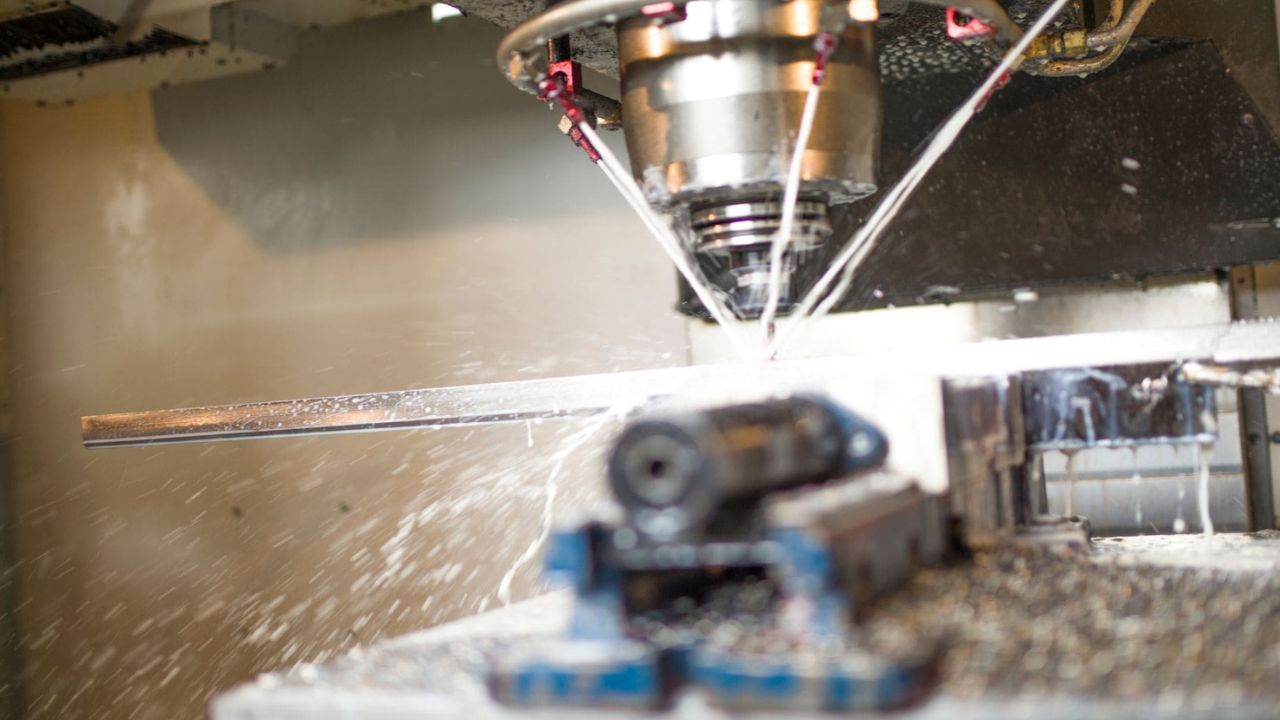

Precision machining involves the process of removing material from a workpiece to create intricate components with tight tolerances and high surface quality. The choice of materials for precision machining is crucial, as different materials exhibit varying properties, including hardness, strength, thermal conductivity, and corrosion resistance. Manufacturers select materials based on the specific requirements of the components and the intended applications.

The selection of materials for precision machining depends on the specific requirements of the components, including mechanical properties, environmental conditions, and intended applications. By choosing the appropriate material, manufacturers can ensure that the machined components meet the desired specifications and deliver optimal performance in their respective industries. You can find the 3ERP among one of the best cnc precision machining services suppliers so get details from here.

Types of Materials for Precision Machining

Here are some types of materials commonly used for precision machining:

Metals

Metals are widely used in precision machining due to their excellent mechanical properties and versatility. Stainless steel is corrosion-resistant, making it ideal for applications in harsh environments. It offers good mechanical strength and is commonly used in industries such as aerospace, automotive, and medical devices.

Aluminum is lightweight, highly machinable, and has good thermal conductivity. It finds applications in aerospace, automotive, and electronics due to its favorable strength-to-weight ratio. Titanium is known for its high strength-to-weight ratio, corrosion resistance, and biocompatibility. Brass is an alloy of copper and zinc, offering excellent machinability and electrical conductivity.

Plastics

Plastics are widely used in precision machining due to their low cost, lightweight nature, and ease of fabrication. Acetal is a high-strength, low-friction plastic often used in precision gears, bushings, and bearings due to its wear resistance and dimensional stability. Polyethylene is lightweight, chemically resistant, and has excellent electrical insulation properties.

It is used in various applications, including electrical components and medical devices. PTFE, commonly known as Teflon, has a low coefficient of friction and excellent chemical resistance. It is used in applications requiring non-stick properties, such as seals, gaskets, and bearings.

Ceramics

Ceramic materials exhibit exceptional hardness, wear resistance, and high-temperature stability, making them suitable for precision machining in demanding environments. Alumina ceramics are known for their high mechanical strength, electrical insulation, and resistance to wear and corrosion. They find applications in cutting tools, wear-resistant components, and electronic substrates. Zirconia ceramics offer high fracture toughness and excellent thermal shock resistance. They are used in applications such as dental implants, ball bearings, and cutting tools.

Composites

Composite materials are engineered materials made by combining two or more constituent materials to achieve specific properties. Carbon Fiber Reinforced Polymers (CFRP) composites are lightweight and have high strength-to-weight ratios. They are used in aerospace, automotive, and sports equipment for their exceptional strength and stiffness. Glass Fiber Reinforced Polymers (GFRP) composites offer good strength, low cost, and corrosion resistance. They find applications in construction, automotive parts, and marine components.

Super Alloys

Superalloys are high-performance materials designed to withstand extreme temperatures and harsh environments. They are commonly used in precision machining for components subjected to high stress and temperature conditions. Inconel alloys are known for their excellent corrosion resistance, high-temperature strength, and oxidation resistance. Hastelloy alloys offer exceptional corrosion resistance, making them suitable for applications in chemical processing, petrochemical, and nuclear industries where exposure to aggressive environments is common.

Tool Steels

Tool steels are specifically designed for cutting tools and molds used in precision machining processes. They offer high hardness, wear resistance, and thermal stability. High-speed steel (HSS) alloys contain tungsten, molybdenum, and vanadium, providing excellent hardness and wear resistance at high temperatures. Carbide tools are made of cemented carbide, a composite material of tungsten carbide particles bonded with a metallic binder. Carbide tools offer high hardness and wear resistance, making them suitable for machining hard materials, such as steel, titanium, and composites.

Final Words

There are numerous reputable suppliers of CNC precision machining services worldwide, ranging from large-scale manufacturing companies to specialized shops offering precision machining solutions. When choosing a supplier for CNC precision machining services, it’s essential to consider factors such as expertise, equipment capabilities, quality certifications, lead times, and customer reviews.